Product Description

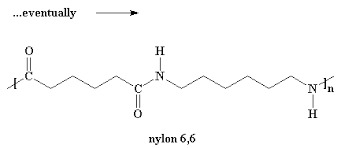

Nylon 66

Description

Nylon-6,6 (PA66) is semi-crystalline polyamide commonly used in fiber applications such as carpeting, clothing, and tire cord. It is also used as an engineering material in bearings and gears due to its good abrasion resistance and self-lubricating properties.

Properties

- Glass transition temperature: 50oC.

- Melting temperature: 255oC.

- Amorphous density at 25oC: 1.07 g/cm3.

- Crystalline density at 25oC: 1.24 g/cm3.

- Molecular weight of repeat unit: 226.32 g/mol.

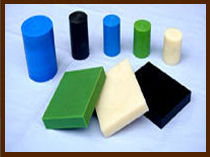

Engineered for Demanding Industrial ApplicationsNylon 66 stands out for its broad working temperature range (-40C to 180C), superior tensile and impact strength, and robust resistance to wear and chemicals. Its versatility supports custom sizes and shapes, meeting various industrial requirements. This high-performance material delivers reliability and safety for automotive parts, machinery, and electrical components.

Versatile Processing and Installation OptionsFormulated for injection molding, extrusion, and precision machining, Nylon 66 adapts to multiple manufacturing processes. With custom sizes, modular installation, and direct assembly, this polymer is suitable for a wide variety of technical requirements, optimizing performance and efficiency in production and end-use environments.

FAQs of Nylon 66:

Q: How does Nylon 66 maintain its properties at high temperatures?

A: Nylon 66 is heat resistant up to 180C, enabling consistent performance in environments with elevated temperatures. Its molecular structure helps retain strength and dimensional stability, making it ideal for applications with rigorous thermal demands.

Q: What are the main industrial uses of Nylon 66 with enhanced properties?

A: This grade of Nylon 66 is widely used in automotive parts, electrical components, and industrial machinery. Its high load-bearing capacity, excellent electrical insulation, and chemical resistance make it suitable for demanding applications.

Q: When is Nylon 66 preferred over other engineering plastics?

A: Nylon 66 is chosen in scenarios requiring high tensile strength, heat resistance, and low water absorption, especially where long-term durability and safety are critical, such as in automotive, electrical, and heavy industrial settings.

Q: Where can Nylon 66 components be used effectively?

A: Nylon 66 components are effective in environments requiring high mechanical strength, low moisture uptake, and exposure to chemicals, such as automotive engine compartments, electrical housings, and industrial equipment.

Q: What processing methods are used for manufacturing Nylon 66 products?

A: Nylon 66 products can be manufactured using injection molding, extrusion, and machining processes. These allow for a variety of forms such as rods, sheets, and granules in customized sizes and specifications.

Q: How does the materials self-extinguishing property benefit industrial users?

A: Nylon 66s self-extinguishing nature enhances safety, particularly in electrical and automotive industries, reducing fire risks and contributing to compliance with stringent safety standards.

Q: What are the benefits of choosing UV-resistant and corrosion-resistant Nylon 66?

A: UV resistance ensures longevity and color stability when exposed to sunlight, while excellent corrosion resistance protects components from acids, alkalis, and solvents, extending product life and reducing maintenance in harsh environments.