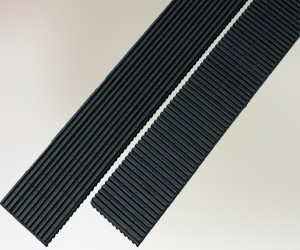

Product Description

Nitrile rubber sheet

NBR nitrile rubber sheeting is specially formulated to prevent oil attack, meaning its mechanical properties remain intact even in direct contact with oils and grease.

Our range includes nitrile rubber sheeting specifically created to withstand contact with industrial oils, hydrocarbons, kerosene and high temperatures. Our nitrile rubber sheeting is mainly used in the manufacture of seals and other elements for industrial environments, in food grades for the food processing and health industries, and in special applications for transformer oil or dielectric oils for electrical installations and equipment.

Properties

Good general resistance to oils.

Good mechanical properties especially tensile strength, flexibility, compression set and impermeability to gases.

Moderate ageing properties.

Temperature range: -30º C to +120º C, with the possibility of reaching -40ºC.

Good adhesion to metal.

Moderate resistance to low temperature.

Resistance to Chemicals; good resistance to inorganic chemical products except antioxidant agents and chlorine, and has satisfactory resistance to general hydrocarbons. Being a polar rubber means it is not recommended for use with polar liquids like ketones, ethers and amines. Limited resistance to aromatic hydrocarbons.

Applications

- Industrial maintenance

Electrical transformers

- Food Industries

Sealing

Key Features of Nitrile Rubber SheetsThe Nitrile Rubber Sheet delivers outstanding performance with high tensile strength (15-20 MPa) and excellent abrasion resistance. Its material composition includes nitrile polymer, natural rubber, and fillers, resulting in high oil and solvent resistance. The sheets have low water absorption, a smooth finish, and a self-extinguishing flame resistance level, making them suitable for industrial settings requiring reliable and durable solutions.

Applications and UsageDesigned for versatility, the Nitrile Rubber Sheets are widely used for industrial gaskets, seals, and oil-resistant flooring. Their custom sizing options and easy-to-install 1-meter width rolls offer convenience for various industrial environments. The sheets can handle application temperatures from -20C to +120C, suiting both hot and cold operations, and their moderate insulation capacities allow use in locations requiring some electrical safety.

FAQs of Nitrile Rubber Sheet:

Q: How is the Nitrile Rubber Sheet manufactured?

A: The Nitrile Rubber Sheet is produced through compression moulding and is sulfur-cured. This process ensures high density, durability, and uniform thickness, which contribute to its strength and reliability in industrial applications.

Q: What are the recommended storage conditions for these sheets?

A: It is best to store the Nitrile Rubber Sheet in a dry environment away from direct sunlight. Proper storage helps preserve its structural integrity, maintaining performance and longevity.

Q: Where can the Nitrile Rubber Sheet be used effectively?

A: These sheets are ideal for locations requiring oil and solvent resistance, such as industrial settings for gaskets, seals, and oil-resistant flooring. They can be reliably used within the application temperature range of -20C to +120C.

Q: What benefits does the product offer in terms of chemical and flame resistance?

A: The Nitrile Rubber Sheet has good resistance to acids and alkalis and is self-extinguishing, providing safety in environments exposed to chemicals or intermittent flame contact.

Q: When should I consider using Nitrile Rubber Sheet over other rubber types?

A: Choose Nitrile Rubber Sheets when high oil, solvent, and abrasion resistance are needed, and moderate electrical and weather resistance is acceptable. It is especially suitable for industries dealing with oils and chemicals.

Q: What standards does the Nitrile Rubber Sheet conform to?

A: This product complies with ASTM D2000 and IS 638 standards, ensuring its quality and suitability for industrial use in India and international markets.

Q: How do I select the right size and thickness for my application?

A: Custom sizes are available, with standard thicknesses ranging from 5 to 10 mm and lengths up to 10 meters per roll. Select dimensions based on specific application needs to ensure effective sealing, flooring, or insulation.